Written By Fuji Machine Manufacturing Co., Ltd. SMT Equipment Information Systems & Training

No Polarity

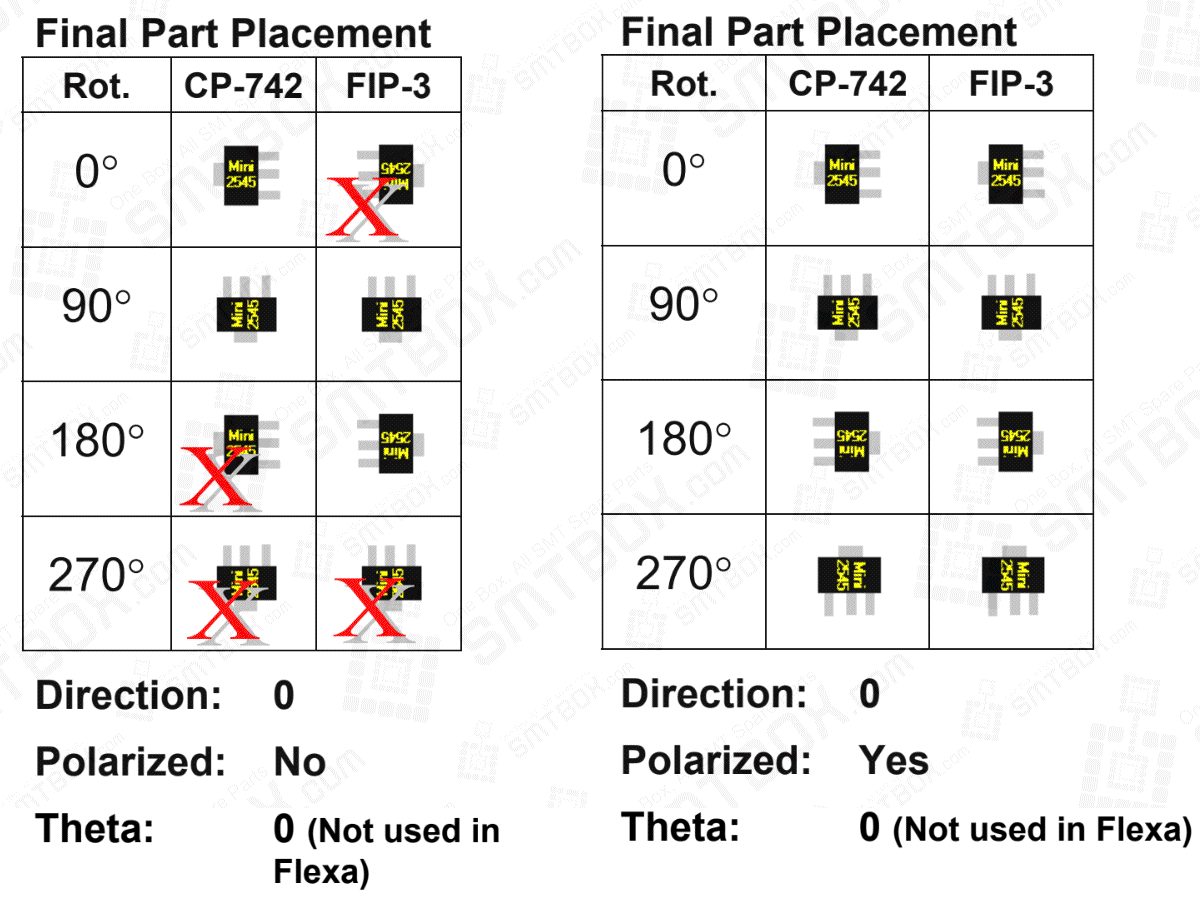

For the first example, the three settings are:

Direction: 0

Polarized: No

Theta: 0 (Not used in Fuji Flexa)

In the table to the left, the actual part placement of the mini-molds by the two machines is shown with the completed panel in the same orientation as shown in the host system view. The Xs mark the parts that do not correspond to the view from the host system.

The reason for the errors is that a mini-mold is a part that has polarity, but in this example the polarity setting was set to ìNo?. Polarity must be used when the part is not symmetrical, electrically and/or physically. When a part has no polarity, the part is symmetrical both physically and electrically. A basic example of a part with no polarity is a rectangle resistor. When the polarity setting is set to ìNo? for a part, Fuji machines minimize the rotation of the part to improve speed. For example, a rotation of 180° is the same as a rotation of 0° for a part with no polarity. When a Fuji placing machine is to place this part at 180° degrees, it determines that since 0° and 180° degrees rotation are the same and 0° requires less rotation, it does not rotate the part.

The same thing occurs when the part is rotated 270° degrees. Since 90°and 270° degrees are the same for a part with no polarity, the machine minimizes rotation and only rotates the part 90° degrees. This can be seen with the example of the mini-mold. Notice that mini-molds rotated 90° degrees and 270° degrees are oriented the same on the panel.

The reason for the difference between the CP-742 and the IP-3 for 0° degrees and 180° degrees is due to the difference in the machine types. The CP-742 is a turret type machine, so after a part is picked up from the feeder the head carries the part around the turret 180° degrees before placement, thus the part is also rotated 180° degrees. On the IP-3, the part is picked from the feeder and then placed on the board in the same direction as it was picked. Note that a part is being supplied from the back of the machine for both machines, so when a part is picked from the feeder, it is oriented 180° degrees different from the part on the feeder table.

Polarity

In this example, the three settings are:

Direction: 0

Polarized: Yes

Theta: 0 (Not used in Fuji Flexa)

The only setting that has changed from the first example is that polarized has been changed to “Yes”.

In the table to the left, the actual part placement of the mini-molds by the two machines is shown with the completed panel in the same orientation as shown in the view of the host system. As the table to the left displays, the final part placement matches that of the view.

Because polarized has been set to “Yes”, both machines rotated the parts the specified rotation. In addition, the machines have compensated for the difference in machine types automatically. Specifying the correct setting for parts is especially important when using machines that can place parts from both sides (e.g., QP-3-series) since it is possible that the feeder for the part can be set on either side. If polarity is properly set, the parts will be placed with the correct orientation regardless of the side or machine from which the part is picked.

In summary, when a part is not symmetrical, electrically and/or physically such as with the mini-mold, the polarized setting must be set to ìYes?. When a part does not have polarity such as with a resistor rectangle, the polarized setting can be set to “No” to minimize the rotation required to place the part.

If in doubt about the proper polarity setting for a part, the safest setting is ìYes?. If a part does not have polarity and “Yes” is specified, there will be no problems with the produced panel. However, if a part does have polarity and ìNo? is specified, there is an extremely high chance that there will be problems with the produced panel.

In the next example, the effects of Theta are examined.