1. Body

Length (X): Specify X-direction length of the part’s body size.

Width (Y): Specify Y-direction length of the part’s body size.

Length Tolerance (X): Specify the part’s X-direction length tolerance.

Width Tolerance (Y): Specify the part’s Y-direction length tolerance.

Height: Specify the part’s height.

Height Tolerance: Specify the part’s height tolerance.

Color

For the NXT, this is used for vision processing of parts. Parts that are using the body detection vision types must have the color specified as “White”.

The vision type that this setting must be “White” are: 60, 61, 62, 63, 65, 71, 74, 80, 153, 160, and 252.

Parts using these vision type that do not appear “white” in the images (the body is completly black with no leads), cannot be vision processed using these vision types.

2. Lead

Pitch Tolerance

It is the tolerance allowed for the deviation from the pitch as a percentage of the lead pitch length. If no setting is made here, processing is carried out using a default value of 30%.

3. Element Information

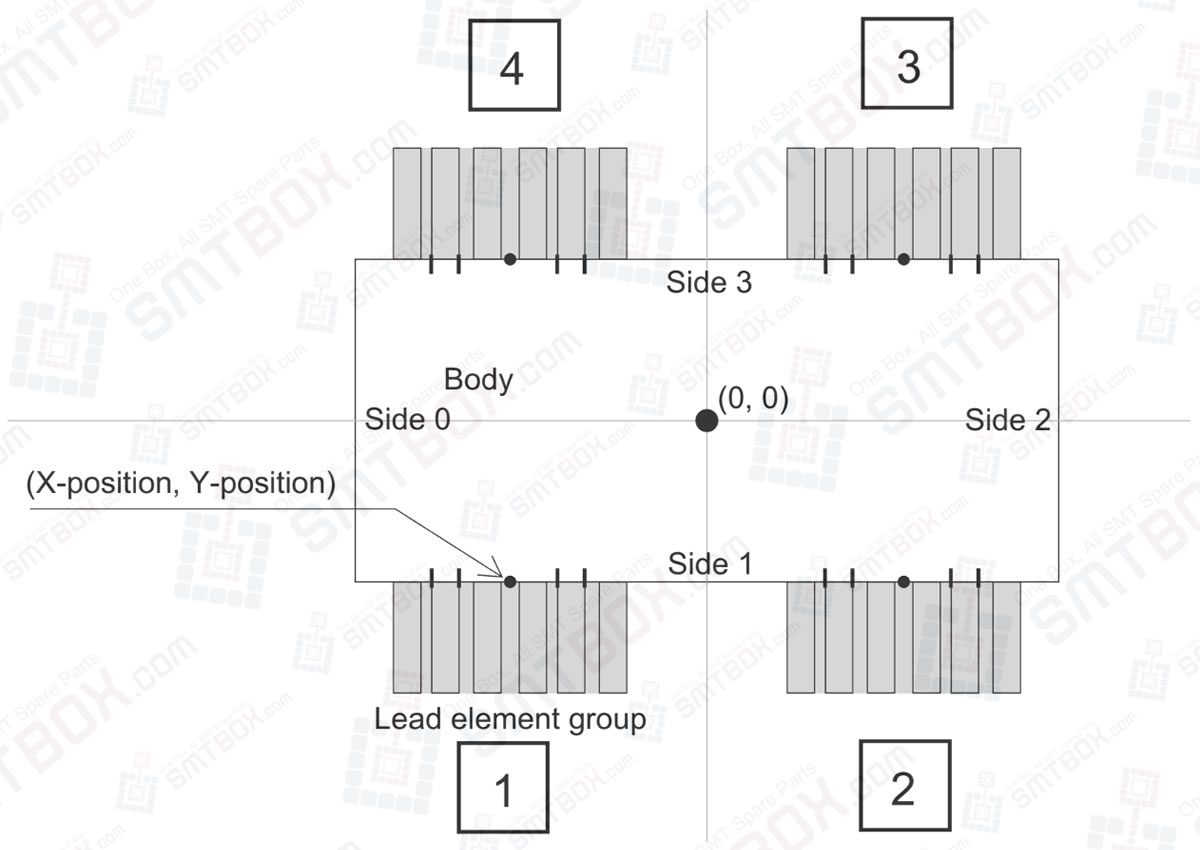

Set element related data. An element is a group of leads on the same side of a part which have the same length, width, and pitch. As there may be several elements on a part, numbers are assigned to the elements for identification purposes.

Double-click the data cell for this field and the [Element Information] dialog box displays.

Position X, Y: This expresses the X- and Y-coordinates from the center of the part to the point on the side of the part that is central with the element. (Refer to the figure above)

Side: Specify the side on which the element is located. Side numbers should always be assigned as shown in the above figure (at direction 0).

P_pattern: Specify how the leads appear to the vision processing system. Select the P Pattern from the choices that matches the lead image.

Refer to section 3.5 P_pattern Details for details on settings for this item. The table below lists the common P_pattern settings for the NXT.

Result

Specify the type of check which will be performed on the leads in the element. Normally, this is set to [Inspect]. The check items are described below.

Group: Vision Processing Options

Setting no.1: Inspect

Description: Specifies the usual vision processing inspection without special checks. This setting is specified for standard parts which do not have special shapes.

Setting no.2: Don’t inspect

Description: The element is not inspected. Virtual lead This setting is used to define virtual leads. When the part is inspected, the vision processing system verifies that there are no leads in the virtual lead area. This function is useful for polarity checks.

Setting no.3: Matrix

Description: Use this for BGAs and flip chips. Because the leads are defined as a two dimensional array on these parts, two records are necessary to define one element. Result is set to “Inspect” in the first element and in the second element result is set to “Matrix.” The “Matrix” setting alerts the vision processing system that this is a grid-type part and that two consecutive element records describe one element.

Group: Check Items

Setting no.1: No length tolerance check

Description: Select this item to disable the lead length tolerance check. This setting is used when there is a wide variation in the length of the leads.

Setting no.2: No width tolerance check

Description: Select this item to disable the lead width tolerance check. This setting is used when there is a wide variation in the width of the leads.

Setting no.3: First pin check

Description: Use this to check that there is no lead to the left of the very first lead detected (leads are inspected from left to right).

Setting no.4: Last pin check

Description: Select this item to enable the last pin check function. In left to right vision processing of leads, this function verifies that there is no lead to the right of the last detected lead. In top to bottom vision processing of leads, it verifies that there is no lead below the last detected lead.

Note: Not supported for No center length tolerance check and No center width tolerance check.

Quantity

Specify the number of leads in the element.

Pitch

Specify the pitch of the element leads.

Width

Specify the width of element leads.

Width Tolerance

Specify the width tolerance of element leads.

Length

Specify the length of the element leads.

Length Tolerance

Specify the length tolerance of the element leads.

Center Tolerance

Specify the bend tolerance for the element leads.