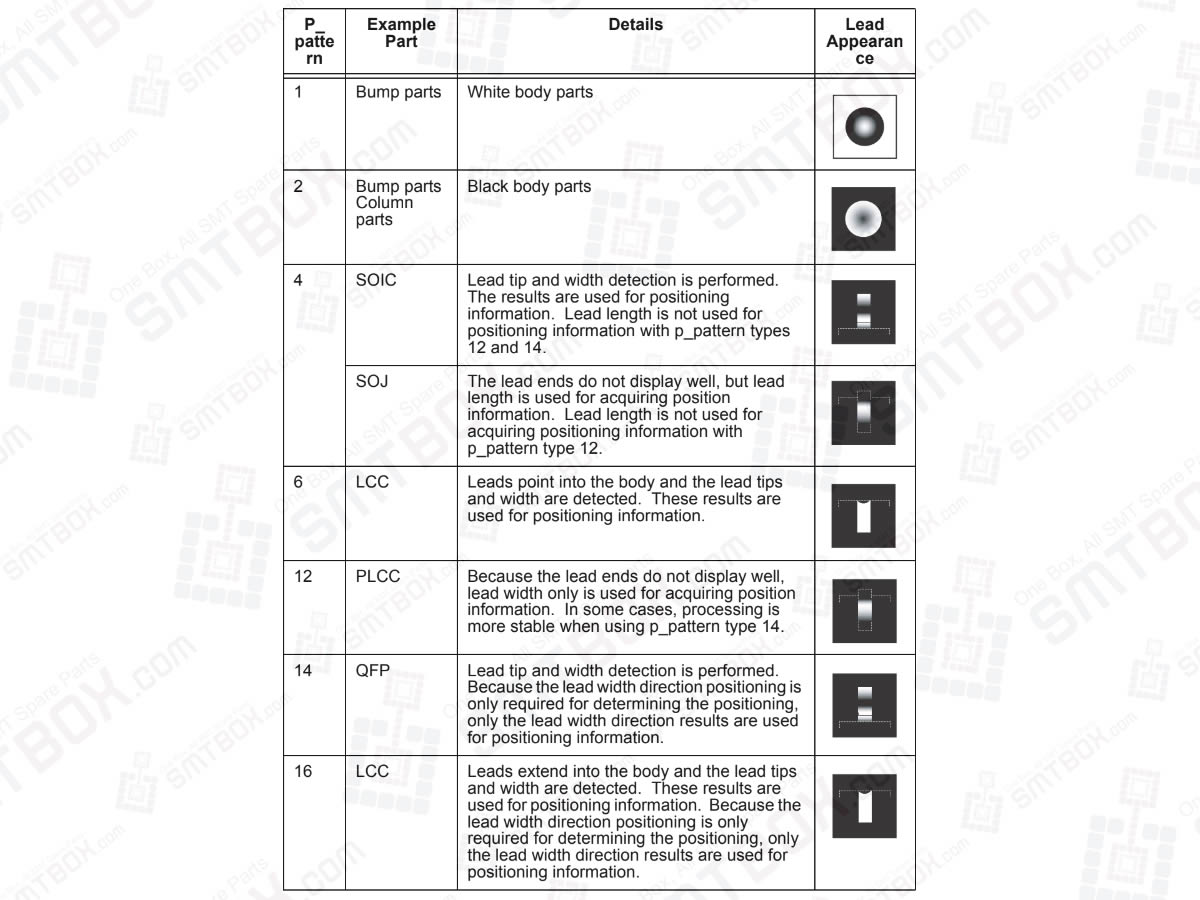

Definition: P_pattern Details

The p_pattern specifies the way the lead appears to the vision processing system and how the processing of the lead information for the part is to be performed. In addition, it is necessary to be aware that the placing position is affected by the specified p_pattern.

1. P_patterns used for the NXT

The following p_patterns are valid for use on the NXT with the frontlight system.

P_pattern: 1

Example Part: Bump parts

Details: White body parts

P_pattern: 2

Example Part: Bump parts Column parts

Details: Black body parts

P_pattern: 4

Example Part: SOIC

Details: Lead tip and width detection is performed. The results are used for positioning information. Lead length is not used for positioning information with p_pattern types 12 and 14.

P_pattern: 4

Example Part: SOJ

Details: The lead ends do not display well, but lead length is used for acquiring position information. Lead length is not used for acquiring positioning information with p_pattern type 12.

P_pattern: 6

Example Part: LCC

Details: Leads point into the body and the lead tips and width are detected. These results are used for positioning information.

P_pattern: 12

Example Part: PLCC

Details: Because the lead ends do not display well, lead width only is used for acquiring position information. In some cases, processing is more stable when using p_pattern type 14.

P_pattern: 14

Example Part: QFP

Details: Lead tip and width detection is performed. Because the lead width direction positioning is only required for determining the positioning, only the lead width direction results are used for positioning information.

P_pattern: 16

Example Part: LCC

Details: Leads extend into the body and the lead tips and width are detected. These results are used for positioning information. Because the lead width direction positioning is only required for determining the positioning, only the lead width direction results are used for positioning information.