These are used for parts with leads that are attached to the body at both ends of the leads and whose lead detection is not stable. The lead widths are checked and the results are used to determine the part positioning.

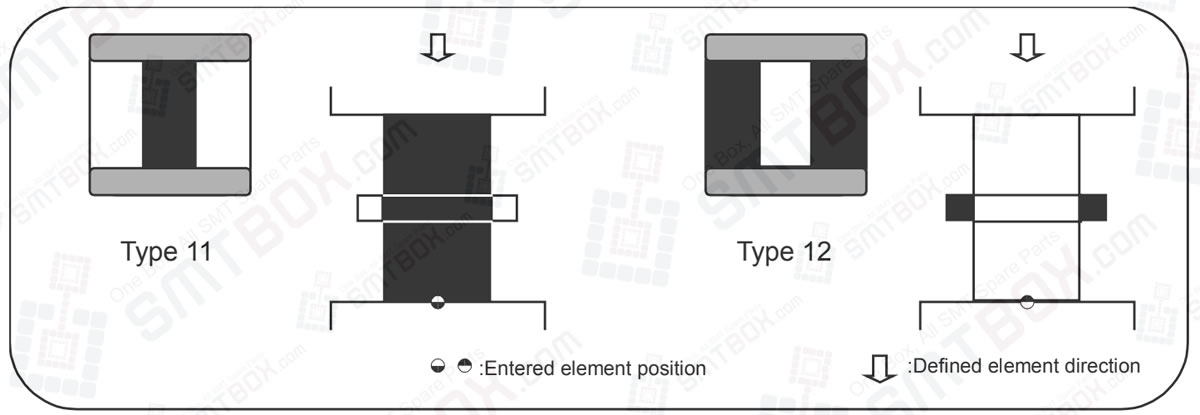

Type 11: The lead appears black and the outside circumference is white.

Type 12: The lead appears white and the outside circumference is black.

Except for parts using vision type 151 and picked up by a mechanical chuck in the Y- direction, these p_patterns can only be used for parts that have leads on two perpendicular sides or more. However, if it is possible to detect either end of the lead in a stable manner, it is recommended to select a different p_pattern (type: 13, 14, 15, 16) that matches the processing conditions.

Furthermore, the information for the part positioning using the lead length is not acquired so these types cannot be used for parts with leads on one side or two opposing sides only.

Example Target Parts

Type 11: TAB parts processed with backlighting.

Type 12: Parts with lead tips that poorly reflect using vision type 151 and a mechanical chuck to pick the part in the Y-direction processed with frontlighting.