You will need the following tools and consumables for maintaining the sleeves.

SIPLACE sleeves maintenance:

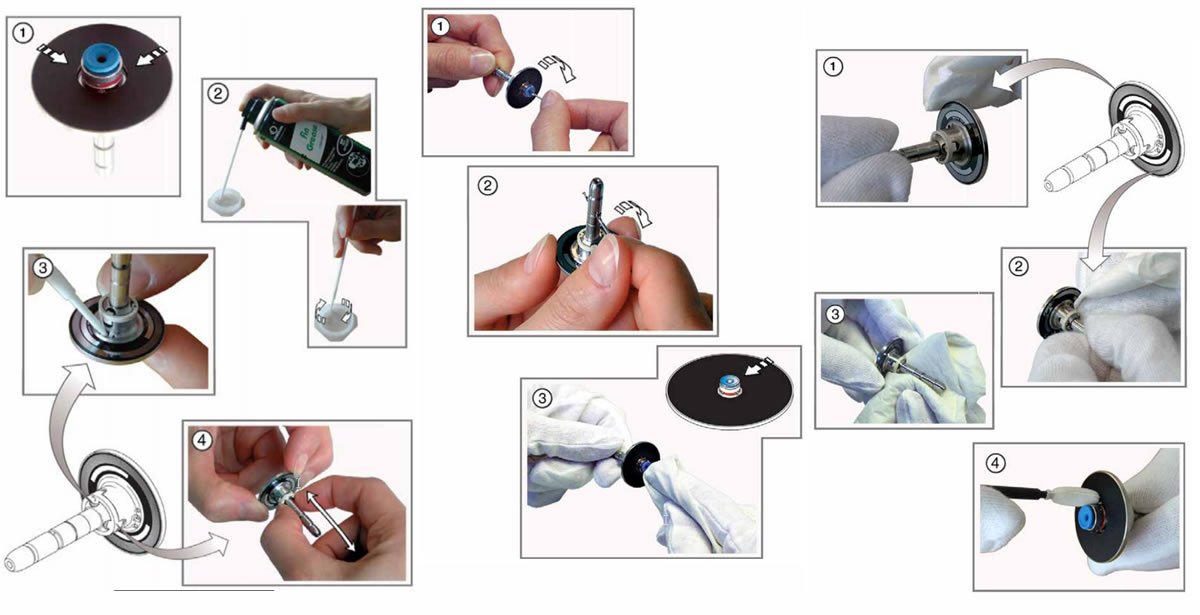

1. Check the foil for damage. If the foil is damaged, send the sleeve to SIPLACE Sleeve Maintenance.

2. Spray a little Teflon grease into a suitable container. Wet the cottonwool buds with Teflon grease.

3. Run the dampened cottonwool bud along the back of the anti-rotation element.

4. Check that the switching ring moves easily in the sleeve. The unit that is moved as a result must not stick or grate. If this is not the case after greasing, send the sleeve to SIPLACE Sleeve Maintenance.

Do not spray the Teflon grease directly with the spray can in order to avoid applying too much and thus damaging the placement head.

To clean, only use ethyl alcohol. Do not use white spirit, otherwise streaks will form on the incremental disk.

Do not use silicon-soluble cleaning agents.

5. Remove the dirt from the longitudinal vacuum hole by turning the 1.4 mm drill bit clockwise in the hole. Turning the bit will remove the dirt from the hole.

6. Remove the dirt from the transverse vacuum hole using the 1.1 mm drill bit.

Wear laboratory gloves for this step.

1. Check the suction plate for damage. Replace it if it is damaged.

2. Clean the sleeve suction plate using a dry, lint-free cloth.

1. Carefully clean the edge of the sleeve using a lint-free cloth moistened with ethyl alcohol.

2. Clean the incremental disk of the sleeve using a lint-free cloth moistened with ethyl alcohol.

3. Carefully clean the shaft of the sleeve using a lint-free cloth moistened with ethyl alcohol.

4. Carefully clean the circumference of the ball catch with a cottonwool bud moistened with ethyl alcohol.