Direction with New Packaging

The packaging is changed to a new packaging in which the part is rotated 90 degrees

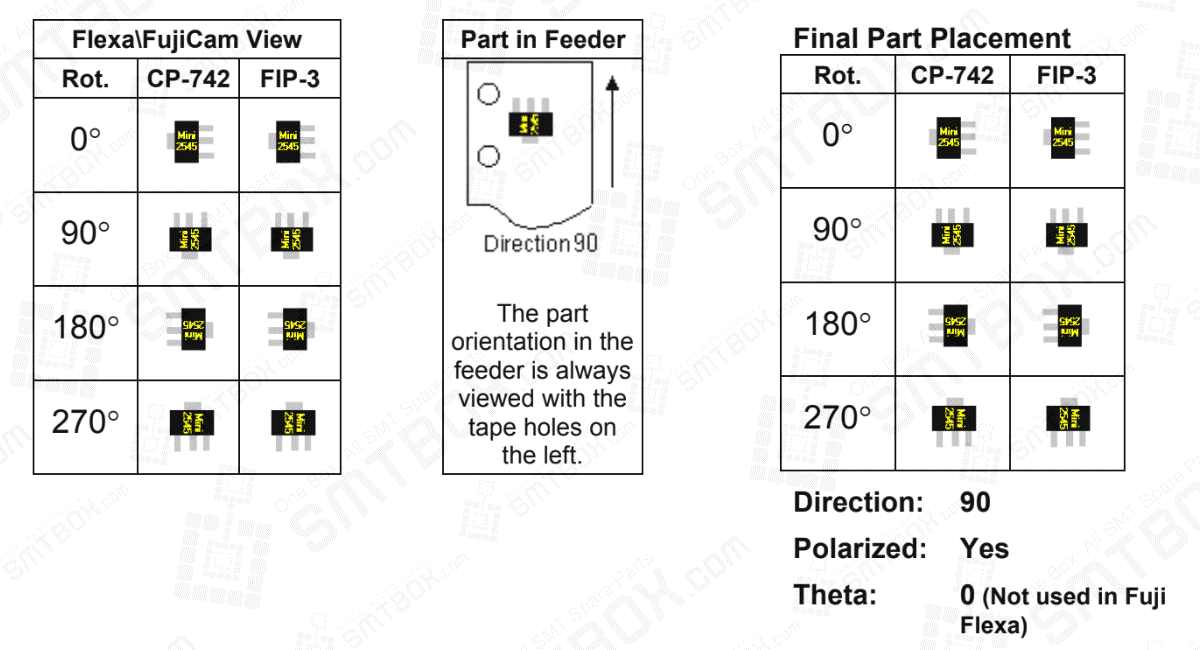

Using the same settings from the previous example, once packaging with the part rotated 90° degrees was used, the machines correctly placed the parts.

Direction is used when the part orientation in the packaging is different than the shape zero orientation. The direction setting should be the difference between the shape zero orientation and the orientation of the parts in the packaging.

Fuji machines automatically compensate for the difference in the partís packaging orientation for vision processing and to rotate the part the necessary amount for placement.

Direction

In this example, the three settings are:

Direction: 90

Polarized: Yes

Theta: 0 (Not used in Fuji Flexa)

The only setting that has changed from the second example is that direction has been changed to 90.

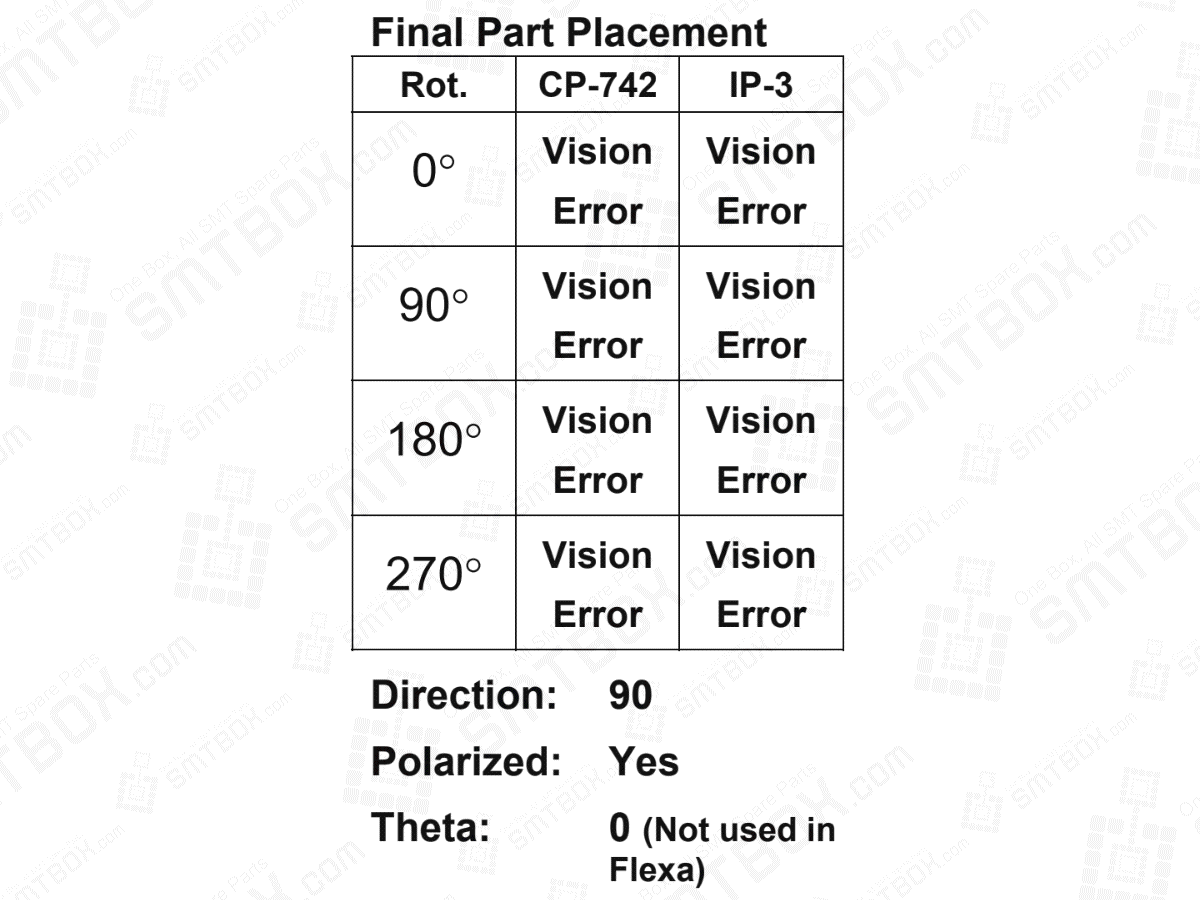

When attempting to place any of the parts, a vision processing error occurs and the part is rejected. When the parts are inspected with trace mode on, orientation of the part that vision processing is examining for is rotated 90° degrees. Because the elements are not found, the part is rejected. This occurred for parts that are being placed from the original packaging.