Insertion Machine Division Product Line: Radial 8XT Dual Span & Triple Span Radial Sequencer / Inserters

1. With Manual Load (Shown with In-Line Sequencer):

Constant, High-Speed Radial Component Insertion

VME-Based Machine Controller with Embedded P.C.

Universal’s IM-UPS Menu-Driven Graphical User Interface

Universal’s Positive Axis Control (PAC) Servo Drive Technology

Uninterruptable Power Supply, with Battery Back-Up

Available as a Dual Span (2.5mm/5.0mm) or as a Triple Span (2.5mm/5.0mm/7.5mm)

2. Manual Board Load “Non Pass Through” CE-Compliant

Powered covers leave operator’s hands free to load/unload boards

New circuitry improves interlock recovery time optimizing throughput

Compatible with existing “stand alone” workboard holders

Less floor space required compared to machine with automatic board handling

3. Shown with Straight-Back Sequencer CE-Compliant with Optional Protective Covers

Fast, Reliable PC Board Transfer

Automatic Internal Board Handling System (BHS)

Magazine Loader/Unloader, with Motorized Magazine Staging Buffers

CE-Marked

4. Introduction

The Radial 8XT, which can insert up to 21,000 components per hour, is an exceptionally high speed (0.17 sec./ins.) Radial Sequencer/Inserter.

The Radial 8XT may be configured either as a Dual Span or a Triple Span machine. A Dual Span Radial 8XT inserts 2.5 mm/ 5.0 mm lead span components into printed circuit boards (PC boards).

A Triple Span Radial 8XT inserts 2.5 mm/5.0 mm/7.5 mm lead span components into PC boards.

The Radial 8XT may be configured in a straight back or in-line sequencer configuration, with or without internal board handling or loader/unloader.

Selected configurations of the Radial 8XT are CE marked.

5. Functional Description

Reels or ammo packs of radial leaded components are loaded on the sequencer module, dispensed, and inserted in the programmed sequence.

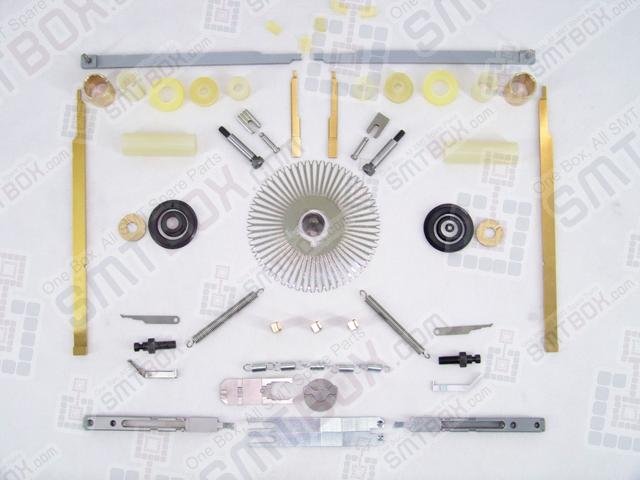

Component dispensing heads remove components from the carrier tape and place them in component carrier clips located on the sequencer chain assembly. The sequencer chain assembly transports the components to the insertion area. While the components are on the sequencer chain assembly, the carrier tape is removed and the component is verified (if equipped with an optional Expanded Range Verifier [ERV]). The component transfer assembly transfers components from the sequencer chain assembly into the insertion head tooling. The insertion tooling guides the leads through the holes in the PC board. The cut and clinch unit cuts, and then forms the leads, securing the component in the PC board.