1) Parts Feeders

F1-82-0603 8mm tape, 2mm index, for 0603 (0201)

F1-82-1005 8mm tape, 2mm index, for 1005 (0402)

F1-84 8mm tape, 4mm index

F1-12 12mm tape

F1-16 16mm plastic tape

F1-24 24mm plastic tape

F1-32 32mm plastic tape

PS-32A 32mm adhesive paper tape

F1-44 44mm plastic tape

F1-56 56mm plastic tape

F2-82-0603 Intelligent Feeder, 8mm tape, 2mm index, for 0603 (0201)

F2-82-1005 Intelligent Feeder, 8mm tape, 2mm index, for 1005 (0402)

F2-84 Intelligent Feeder, 8mm tape, 4mm index

F2-12 Intelligent Feeder, 12mm tape

F2-16 Intelligent Feeder, 16mm plastic tape

F2-24 Intelligent Feeder, 24mm plastic tape

F2-32 Intelligent Feeder, 32mm plastic tape

F2-44 Intelligent Feeder, 44mm plastic tape

F2-56 Intelligent Feeder, 56mm plastic tape

PS-T1S S type stick feeder

PS-T1M M type stick feeder

PS-MS3 Multilane stick feeder

MX-ST2 Manual slide tray feeder

MX-RT1D Removable tray feeder

MX-20D 20-pallet tray feeder, 40 JEDEC trays

MXR-20 20-pallet tray feeder, 20 JEDEC trays

The tape feeders are applicable to reel diameter of 178mm to 382mm.

For detail, refer to the separate Specifications for Feeders.

2) Intelligent Feeder Function Base License

Component Setup Verifier (Full closed loop)

Automatically checks wrong feeder setting and assists inexperienced operators to set feeders correctly. The F2 Intelligent feeders are required. A barcode reader is used for data registration of component information and feeder ID.

3) Intelligent Feeder Function Additional License

Feeder Relocatability

Regardless of the actual feeder location, the machine automatically recognizes each feeder and component.

Feeder setting does not have to be changed. Effective for high-mix and low-volume production.

4) Feeder Bank Changer (CFB-2) Changes feeders in a batch

5) Feeder setting bench Bench for setting reel on tape feeder

6) Feeder Stocker (PFS-3) Feeder stocking wagon with/without Feeder Drive Adapter

* Two-branch Connector (Optional item for Drive Adapter)

* Extension Cable (Optional items for Drive Adapter)

For detail, refer to the separate Specifications for Feeder Stocker.

7) Tape Cutter (TCM-1B) Including a waste tape box

For detail, refer to the separate Specifications for Tape Cutter. No CE conformity.

8) Waste Tape Box Trash tape box

9) Set Master (PCJ-1) Tool for checking pickup points

10) Extra Teach Camera (EXC1)

Attached on the left side of the head assembly

Field of view 20mm square

For teaching operation only

Covers feeder lanes No. 11 to 60

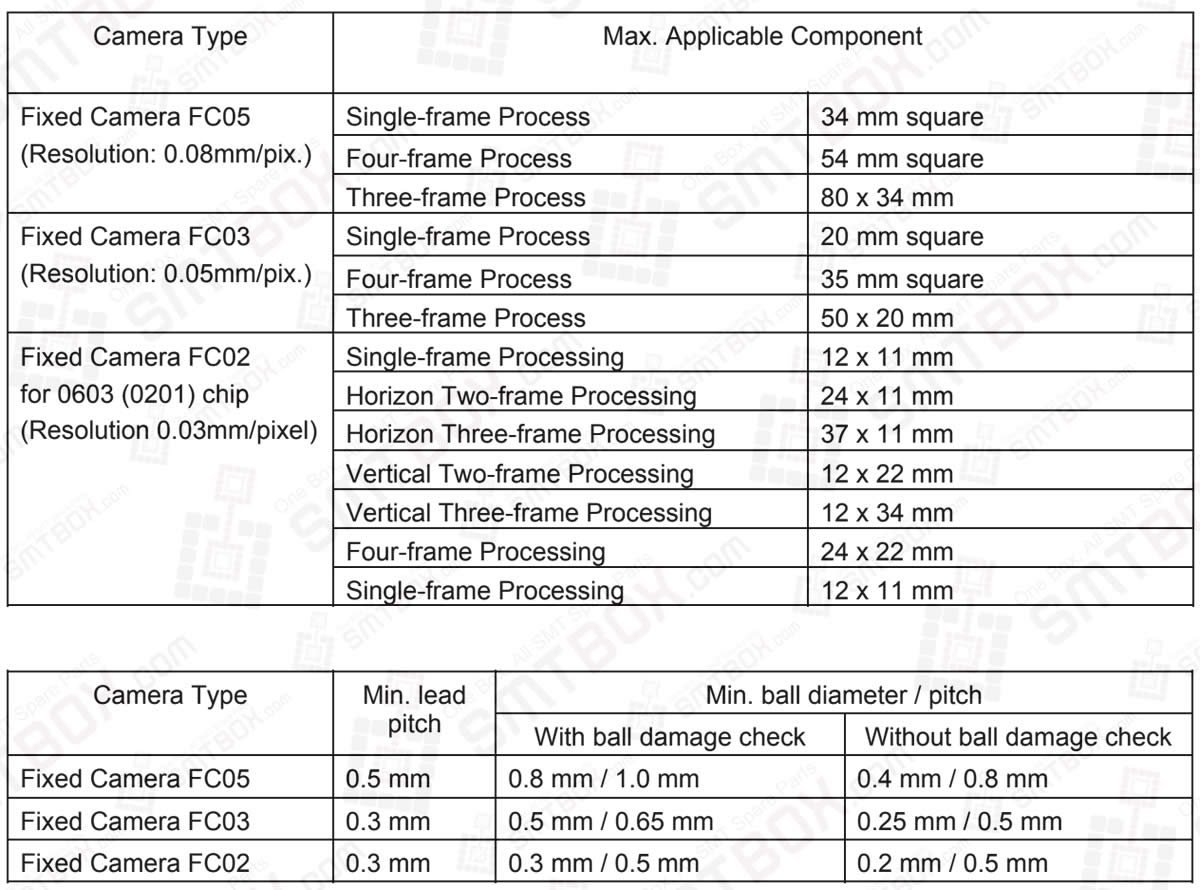

11) Rear Fixed Camera, 2nd

Max. 2 cameras can be fitted to a machine. The 1st camera is standard and the 2nd one is optional.

12) Adjustable PCB Locating Pins 3.0/3.5/4.0mm

13) Measurements Inch

14) Right to Left Flow Conveyor

15) SMEMA Risers For transfer height 950 +/-20mm

16) Conveyor Extension 200mm one side, input side or output side, or both

17) Automatic Conveyor Width Adjustment By motor drive

18) Offline Programming Software (iOSII)

19) Power Transformer For 202/220/240/380/400/415/440V (Standard in export model)

20) Reject Conveyor (RC-54) Conveyor for rejected IC components

For details, refer to the separate Specifications for Reject Conveyor

21) Rear Operation Switches Enables operation by switches on the rear side of the machine.

22) Matrix Backup Clamp Different pins for different board thickness. (Standard in export model)

23) Board Clamp Conveyor Holds and fixes the board by clamping its edges from top and bottom.

Board support pins are commonly usable.

Unplaceable area at board edges is 5mm top side and 6mm bottom side.

For detail, refer to the separate Specifications for Board Clamp Conveyor.

24) 0603 (0201) Scan Camera Field of view 15.4×14.4mm

Component size Minimum 0.6×0.3mm to maximum 12.0×11.0mm

25) UPS-2 Uninterrupted Power Supply

For details, refer to the separate Specifications for UPS-2. No CE Conformity.

26) LCD Monitor 15-inch