Enter the body size and element information for leads or projections. Vision type 160 uses the body center while vision type 165 uses the part center. Element inspection is not performed if the [Result] option for that element is set to “Don’t inspect”.

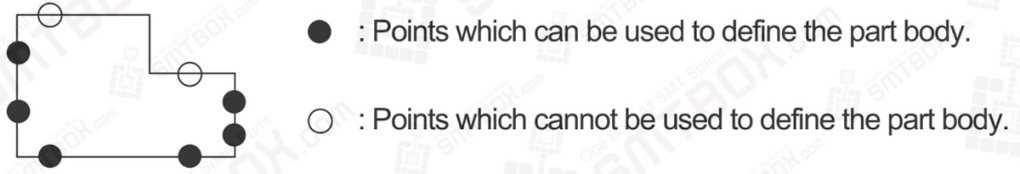

The body inspection points are automatically determined based on the data for leads and projections specified in the element information. When detection positions cannot be properly determined automatically, up to two elements per side can be specified in the element information for the body inspection points. To specify body detection points, specify the side and then enter the coordinates for the points to be inspected in [X] and [Y] items for the position group and enter “0” for all other items for each “detection” element in the element information.

Note: It is necessary to define leads in element information regardless of whether lead inspection is to be performed for those leads or not.

Note: When the body detection option is specified, data should be specified such that there is a minimum of one side where two points can be detected and a minimum of two sides where one point can be detected. If there are an insufficient number of detection points, an error occurs when data is registered.

Note: If the edges of the body of a part are not clearly projected, this may result in an error or a drop in the placing accuracy.

Note: Correct processing cannot be performed if the nozzle protrudes over the edge of the part.

Note: If the straight line obtained from the specified detection points for the same line is not parallel nor perpendicular to the straight line obtained from the detection points of another side, then processing cannot be performed.