Because the lead and body boundary is clearly defined, all four sides of the leads are checked and the results are used to determine the part positioning.

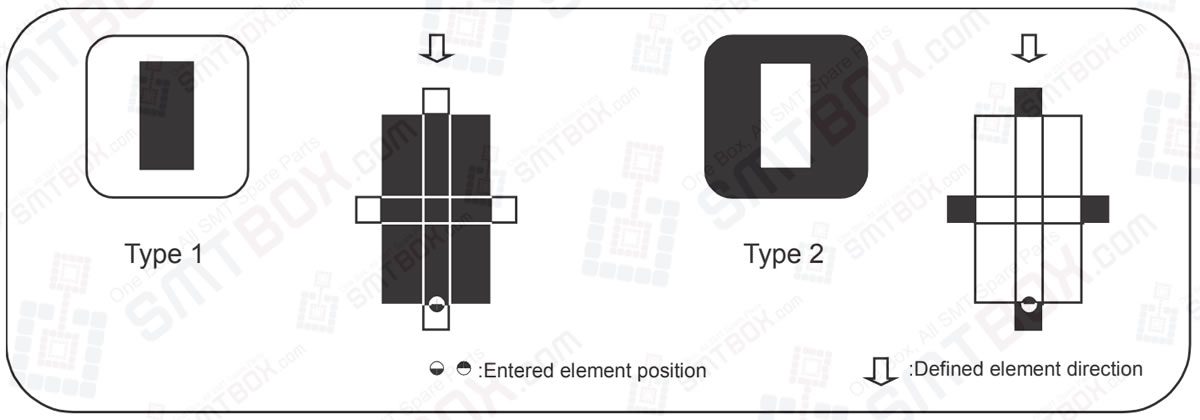

• Type 1: The leads appear black and the outside circumference is white.

• Type 2: The leads appear white and the outside circumference is black

These are primarily used for parts with bumps.

Example Target Parts

Type 1: White body bumped parts processed with frontlighting.

Type 2: Black body bumped parts or CCGAs processed with frontlighting.