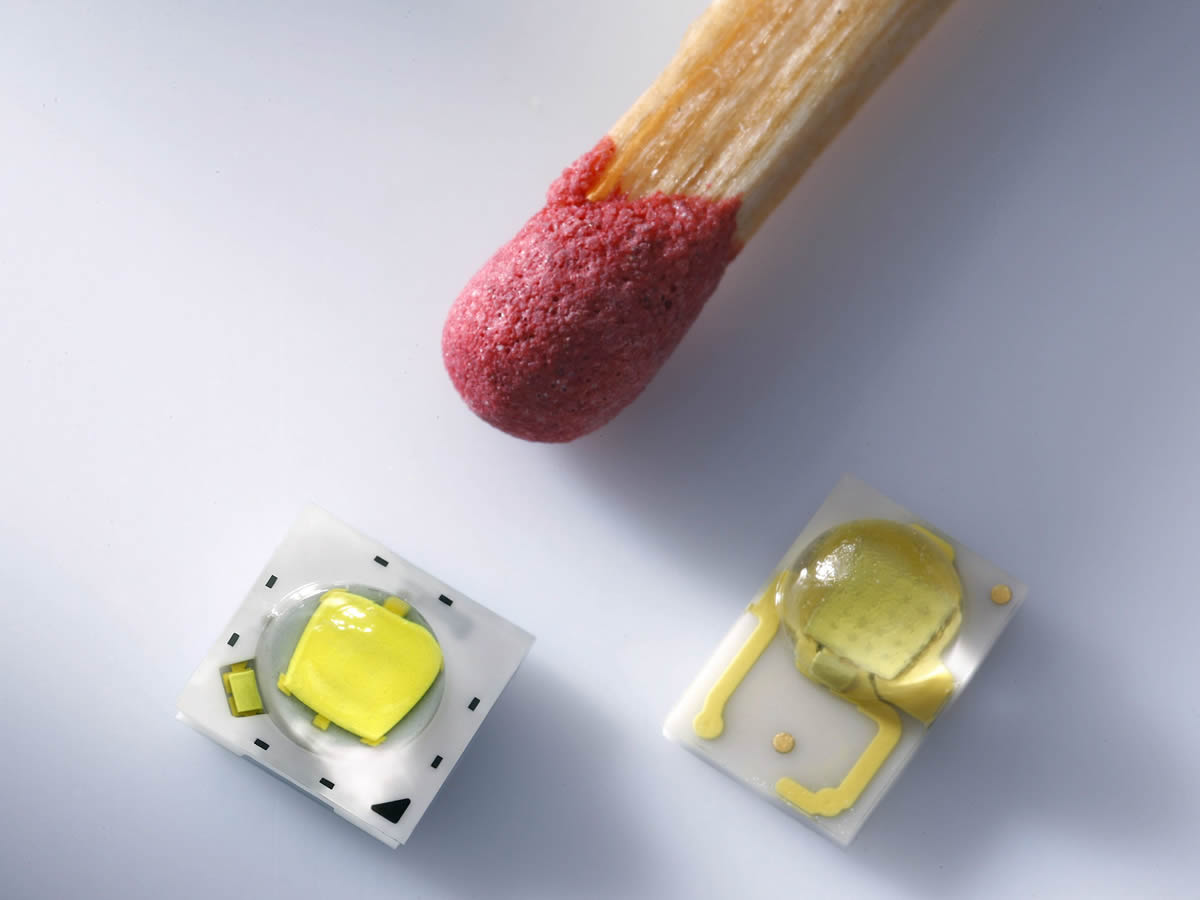

LED lenses are made of resin. Therefore, the lenses sometimes adhere to the top cover tape due to the resin’s stickiness. When the cover tape is peeled from the carrier tape, the LEDs tilt within their cavities, resulting in mounting failure.

It is impossible to eliminate the stickiness of the lens. Please refer to the following pages for the countermeasures against the LED tilting.

3-3-1. Slow down the feeding speed.

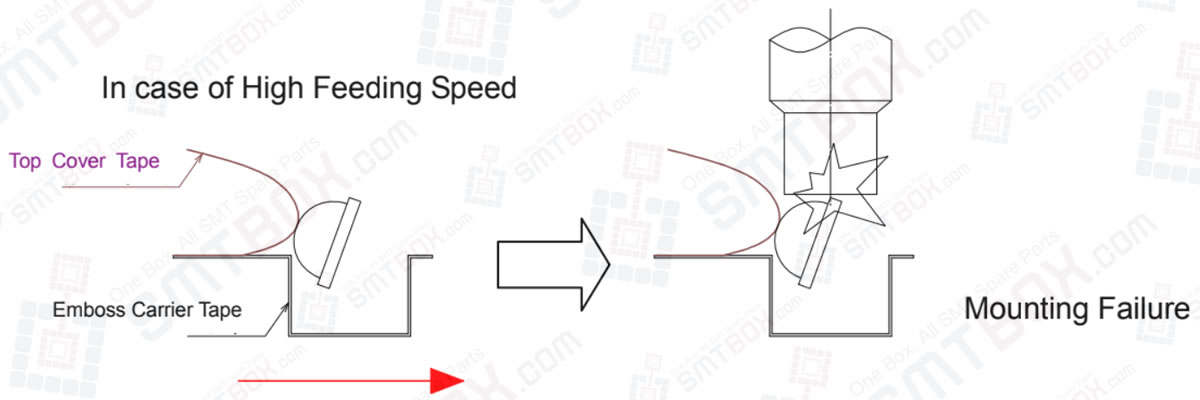

When the feeding speed is fast, the pick-and-place nozzle absorbs the LED before the lens is detached from the top cover tape, resulting in mounting failure.

In case of high feeding speed and mounting failure:

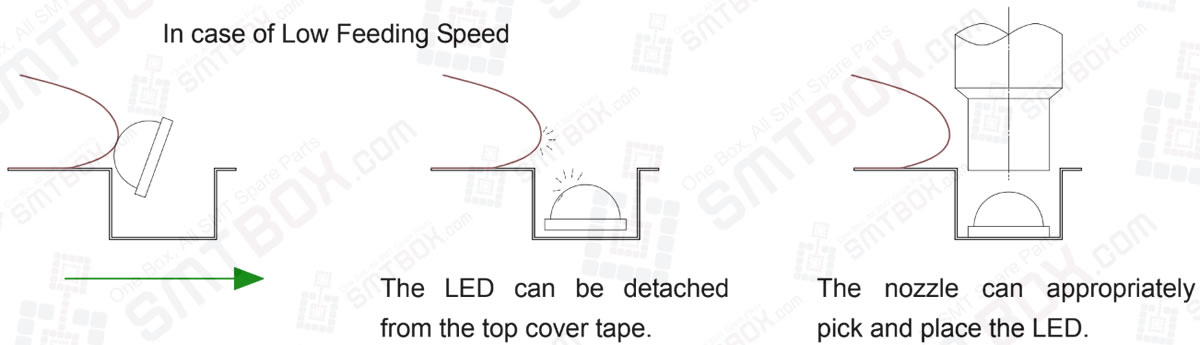

Even when the LED is in contact with the top cover tape; however, by lowering the feeding speed, it can be detached from the tape before absorbed by the nozzle.

In case of low feeding speed, the led can be detached from the top cover tape and the nozzle can appropriately pick and place the LED:

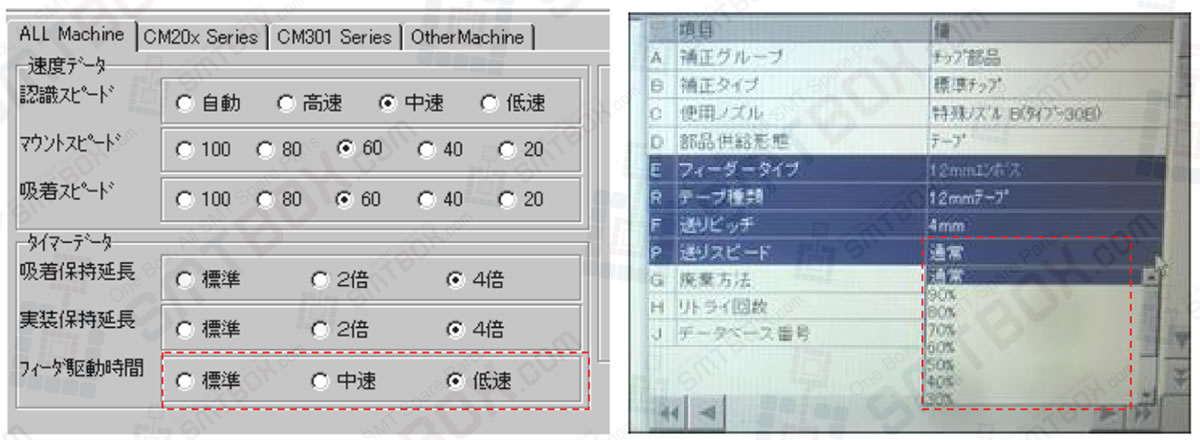

For example, the feeding speed can be changed by the screen as follows: for Panasonic CM Mounter(left one) and Yamaha YS Mounter(right one).

It is impossible to change the feeding speed of Panasonic BM Mounter. Instead, the operation speed of the head can be lowered, lengthening the absorption pitch.