3-1. Problem 1: Damage to the lens during the mounting process

Nichia establishes the optimal absorption method and the optimal cavity shape/size for each LED with a lens.

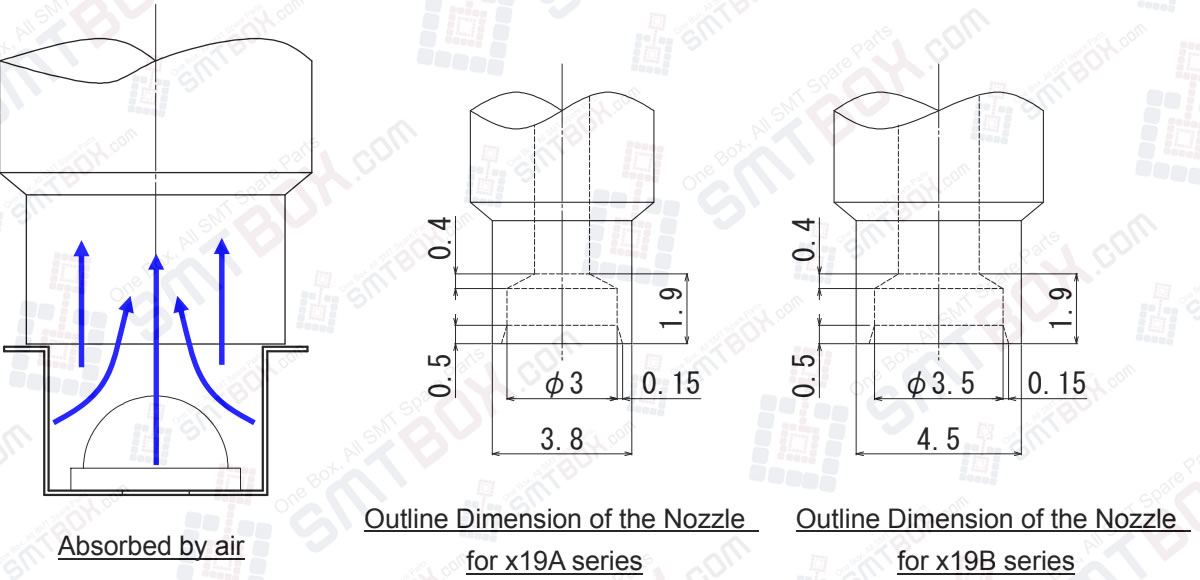

In general, there are two absorption methods; one is the “nozzle insertion system” and the other is the “non-insertion nozzle system.”

3-1-2. Non-Insertion Nozzle System

When the nozzle insertion system is used for the x19 series, the nozzle may touch the lens and apply excessive stress to it, considering the LED’s shape/tolerance and the dimensional tolerance of the nozzle. If the clearance is left between the nozzle and the lens to avoid the contact with each other, it may be impossible to insert the nozzle into the cavity due to the oversized nozzle.

Then, Nichia recommends that the “Non-Insertion Nozzle system” be used for the x19 series. With this system, the nozzle reaches at the top surface of the cavity and absorbs the LEDs.

With the nozzle insertion system, the lens can get damaged due to the insertion pressure of the nozzle. On the other hand, with the non-insertion nozzle system, the nozzle is less likely to apply stress to the lens; only a slight absorption stress is applied to the lens.

Also, superior durability of the nozzle is achieved because of its sufficient thickness, since it does not have to be inserted into the cavities.