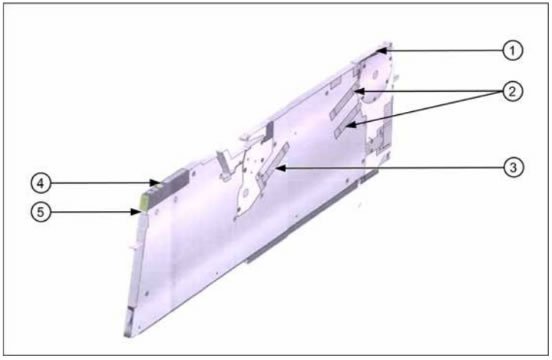

Overview

1. Pickup position

2. Motors for moving components

3. Motor for cover foil

4. Display, operating panel and status display

5. Mechanical and electrical unlocking function

The X feeders enables you to set up a separate feeder for each component used at the machines (single track feeders). This ensures optimum use of the machine locations and optimum configuration of the setups in the placement process.

The X feeders can be logged off should errors occur during production and can then be replaced by other feeders, which are logged back into the production run.

As an option, a splice sensor can be directly integrated into the feeder.

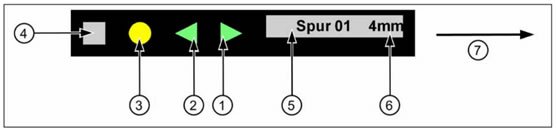

Operator Panel

1. Button “Forward”

Press briefly to move the tape by the set cycle step.

Press for longer to move the tape forwards. Make sure the cover foil is not clamped in.

2. Button “Backward”

Press briefly and release slowly to move the tape backwards by the set cycle step.

Prolonged pressing moves the tape back. ( Both functions should only be performed without the cover foil fitted).

3. Press the “Foil” button to start the foil drive motor. This runs until the foil has been stretched tight and the motor toggle switch turns off or until the timer has counted 30 seconds.

4. Briefly press the “SET” button to switch over to the next menu on the main menu level. Press for longer to request component verification.

5. Display showing track on location

6. Cycle step

7. Transport direction