Procedure

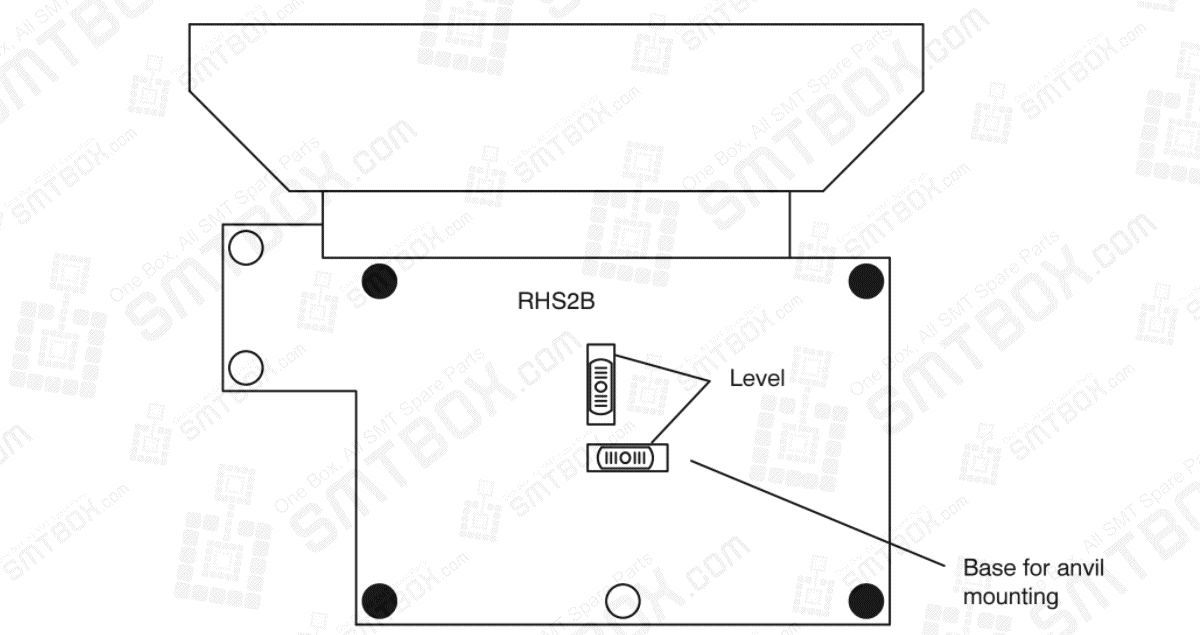

1. Set machine main body accurately on the reference points.

2. Loosen lock nuts securing the adjust bolts.

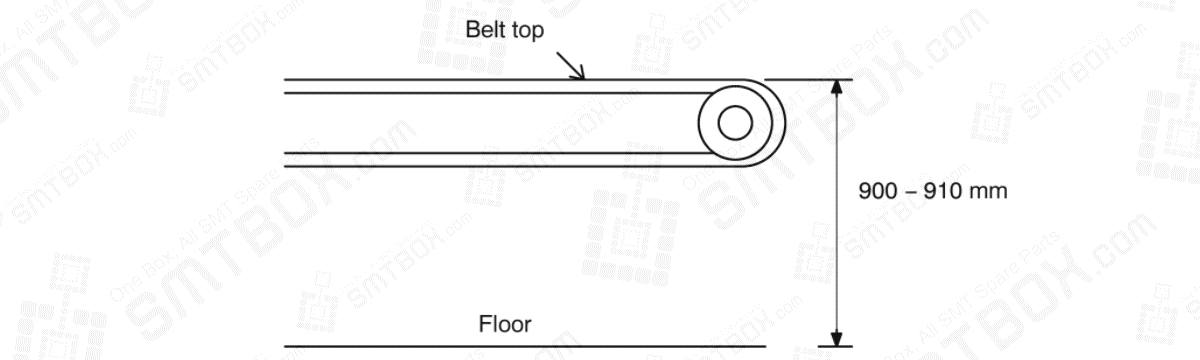

3. Set the height from floor to the transfer belt surface between 900 to 910 mm.

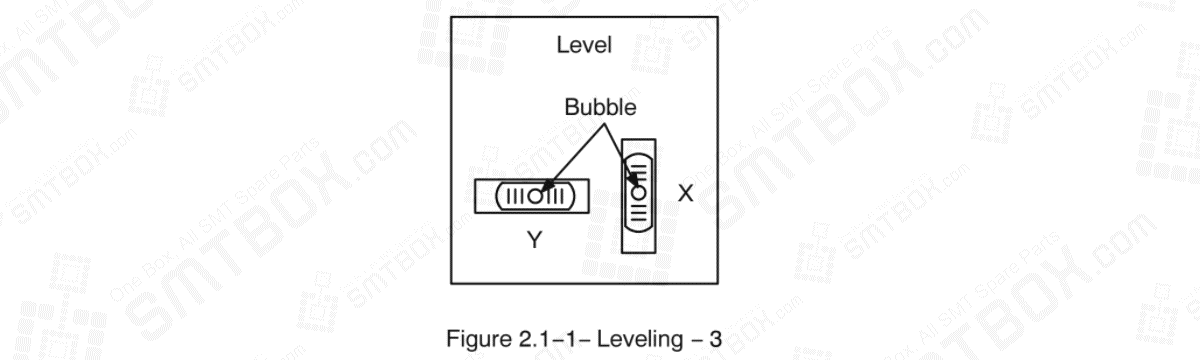

4. Clean the top of the table with waste cloth to remove any foreign substance. Check X and Y directions and judge the current level (against 900?910 mm) to make the temporary level.

5. Make the temporary level so as to check precision of the level. Becomes the basis of leveling.

REFERENCE

Turn the level by 180 and check precision of the level with the bubble position in relation to the scale.

6. Make the leveling of X direction, and then the leveling of Y direction.

7. With leveling of Y direction, recheck leveling of X direction. (If no leveling of X direction has been made, fine?adjust the adjust bolts so as to make both X/Y leveling.)

8. Lock the adjust bolts (legs shown with a black circle). (At this time, check leveling of XY direction. If in error, adjust the adjust bolt on the front side, which facilitates leveling.)

9. Lock also the other adjust bolts (legs shown with a white circle) by adjusting lightly.